PREVENTIVE MAINTENANCE FOR SHUTTLE BOT

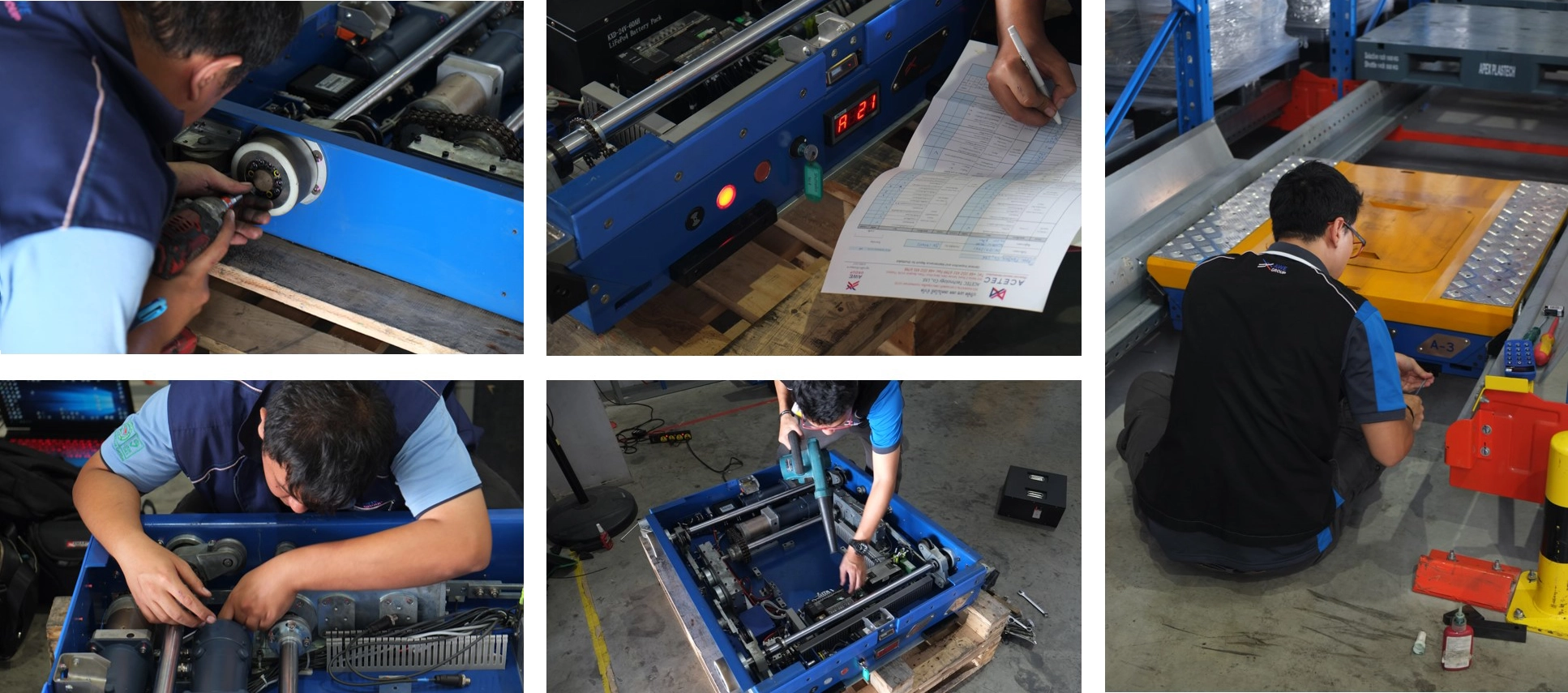

Daily Operator self

- Cleaning and battery checking follow checking list

General Inspection every 3 Month

- Traveling Unit Inspection (Gear, Motor, Tightening Torque)

- Electrical Unit Inspection (Cable Loose, Battery)

- Lifting Unit Inspection (Gear, Motor, Tightening Torque)

- Operation Inspection (Sensor, System Communication)

- Safety Unit Inspection (Safety Sensor, Emergency Button)

- Report Submission

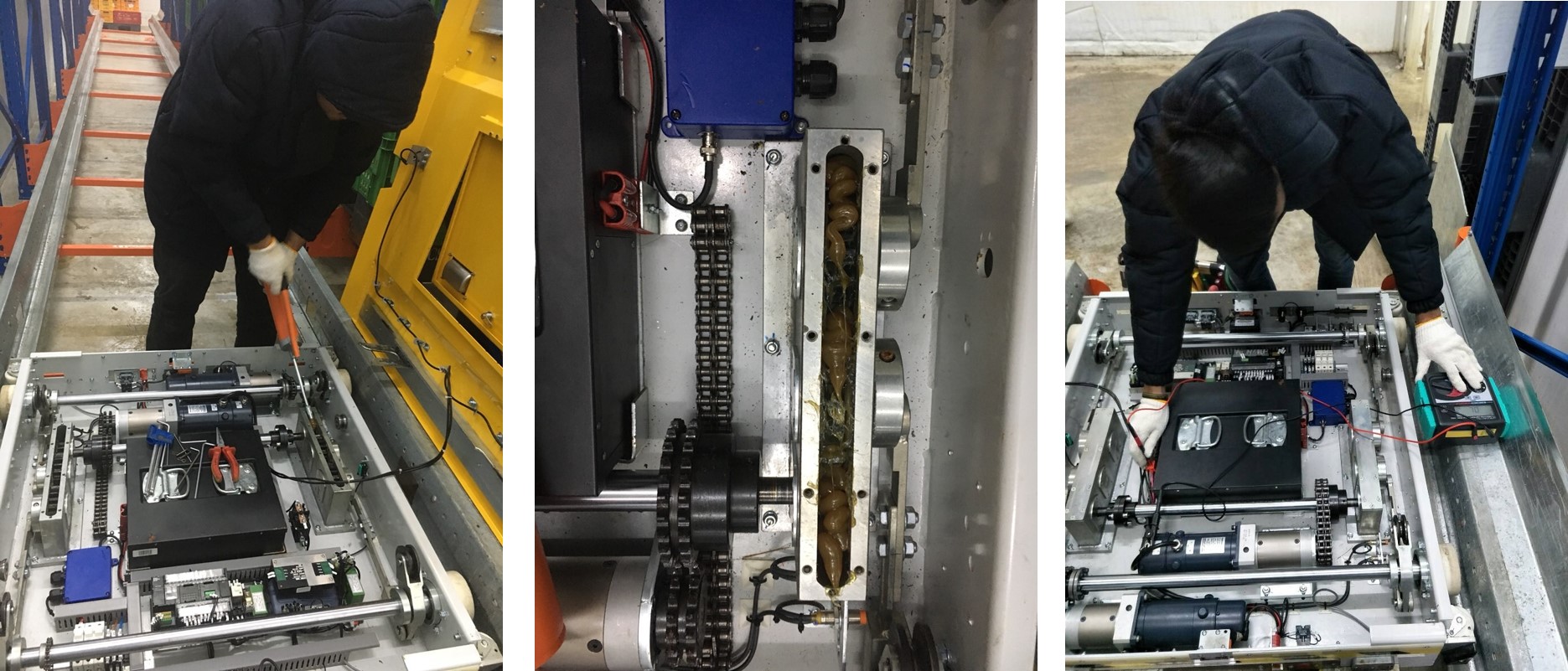

PREVENTIVE MAINTENANCE (COLD STORAGE)

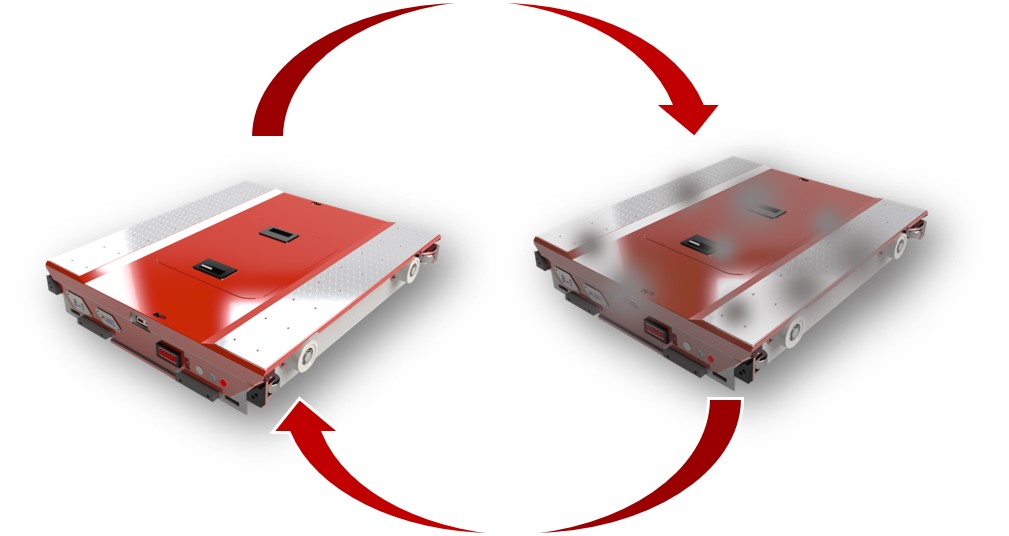

SERVICE SUPPORT

During the warranty period, in case of any necessary adjustment over 3 hrs., ACETEC to support with another ShuttleBot provided within 24 hrs.

After warranty, ACETEC can provide all spare part of ShuttleBot to customer with in 7 days after confirm order.

PREVENTIVE MAINTENANCE for AS/RS

General Inspection 2 times/year

- Lubricant checking and Filling

- Consumable checking and Replacing

- Controller (PLC) checking

- Hoisting, Traveling and Fork drive unit inspection

- Load sensor, Main Body and Trolley inspection

- Operating Function Checking

- Report Submission

Yearly Inspection every 1 times/year

- General inspection

- All control panel and cable checking

- Hoisting, Traveling and Fork all part inspection

- Safety device inspection

- Hanging Chain inspection

- Report Submission